< Previous | Contents | Next >

Section 5 Certificate and Identification

![]()

Ch 2

501. Application

1. The requirements in this Section are applied to which are undergone and passed the prototype test

2. Identification of containers, otherwise specified in

the certification and identification of containers or production unit inspection by the Society.

this chapter, is to be complied with the require-

ments of ISO 6346 (coding, identification and marking)

3. Identification of containers for transport of dangerous goods is to be complied Government regulations and IMDG Code (international maritime dangerous goods dition to the requirements in this chapter.

with the relevant code), etc. in ad-

502. Certificates

1. Approval certificate for manufacturing process (form no. AC-1) shown in appendix 2-1 will be is- sued to the manufacturers which have been examined and approved by the Society.

2. The Society will issue freight container prototype test certificate (form no. CTC-2) shown in ap- pendix 2-2 to the prototype container which is satisfactorily passed the type approval test of the Society.

3. The Society will issue a container production certificate (form no. CTC-3) shown in appendix 2-3 to the type-series containers having satisfactorily carried out production unit inspection of the Society.

503.Marking

1. Marking items

For each container which satisfactorily carried out production unit inspection by the Society, the manufacturer, at least, is to indicate the following markings.

(1) General cargo containers and thermal containers without refrigerating units

(a)

Owner's mark, serial number and check digit

(b) Size and type code

(c)

Rating

(d) Tare

(2) Thermal containers with refrigerating units

(a)

Items prescribed in (1).

(b) Type of refrigerating unit, date of manufacture, and kind of refrigerant.

(c)

Output, revolution, rated voltage, frequency and serial number of phases of the electric mo- tor for refrigerant compressor.

(d) Type of electric source (classification of electric source, I, II or III prescribed in the ISO

1496-2)

(e)

(f)

Full load current and total starting current

Minimum internal temperature and ambient temperature (when the condenser is of aircooled)

(3) Tank containers

(a)

Items prescribed in (1).

(b) Maximum allowable working pressure

(c)

Total capacity

(d) Ullage

(e)

(f)

Test pressure

Date of original hydro test

(g) Next due date of hydro test

(4) All maximum operating gross mass markings on the container are to be made consistent

the maximum operating gross mass information on the safety approval plate.

![]()

(5) Where the containers are provided with cargo hanging arrannements, the maximum service is to be marked at easily visual position on the internal wall of the containers.

with load

Ch 2

![]()

2. Warning marks

The containers which have larger dimensions or greater maximum operating gross mass than those specified in Ch 2, 603. may have warning marks to draw the operator's or carrier's attention.

3. Marking locations

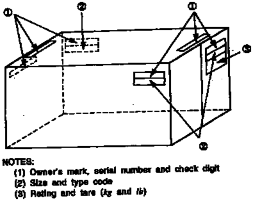

(1) The marking items prescribed in Par 1 (1) to the containers are to be made as specified in Fig 2.1.

(2) The marking items, otherwise specified in (1), are to be properly attached to the containers at easily visible position on door of container.

Fig 2.1 Marking Locations

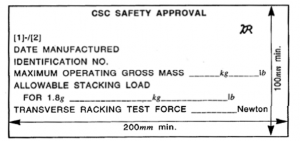

504. Safety approval plate

1. Each container which passed production unit

constructed in accordance with the approved design type and satisfactorily inspection of the Society is to be affixed the safety approval plate for CSC

Convention shown in Fig 2.2 with the Society's inspection stamp.

NOTES:

(1) On line 1, [1] is Country of approval indicated by the distinguishing code and [2] is Approval Reference.

(2) The Plate is to permanent, non-corrosive and fire proof and is to be permanently affixed to the container.

(3) The word "CSC SAFETY APPROVAL" is to a minimum letter height of 8mm and other words and num- bers a minimum height of 5mm. They are to be stamped into, embossed on or indicated on plate surface in any other permanent and legible way.

(4) End and Side Wall Strength to be indicated on plate only if these walls are designed to withstand a force of less or greater than 0.4Pg and 0.6Pg respectively.

(5) If Plate is used for the purpose of showing maintenance dates a blank space is to be reserved at the

bottom.

(6) One door off stacking strength to be indicated on plate only if the container is approved for one door off operation. The marking shall show: ALLOWABLE STACKING LOAD ONE DOOR OFF FOR 1.8g(...kg...lbs). This marking shall be displayed immediately near the stacking test value.

(7) One door off racking strength to be indicated on plate only if the container is approved for one door off operation. The marking shall show: TRANSVERSE RACKING TEST FORCE(...newtons). This marking

shall be displayed immediately near the racking test value.

Fig 2.2 Safety Approval Plate

2. Inspection stamp of this Society is as specified in Fig 2.3.

Fig 2.3 Inspection Stamp

![]()

Ch 2

505. Emblem

Each container which satisfactorily carried out production unit inspection by the Society is to be af- fixed the emblem of the Korean Register of Shipping shown in Fig 2.4 at easily visible position of door in addition to the inspection stamp prescribed in 203.

Fig 2.4 Emblem

506. Manufacturer's name plate

1. Each container which satisfactorily carried out production unit inspection by the Society is to be af- fixed the manufacturer's name plate stamped into followings at easily visible position of door.

(1) General cargo containers and thermal containers

(a) Name of manufacturer

(b) Manufacturer's model No. approved

(c) Date of manufacturing

(d) Manufacturer's serial number

(e) Other items deemed necessary by the Society

(2) Tank containers

(a) Items prescribed in (1)

(b) Test pressure

(c) Date of hydrostatic test

2. The above-mentioned markings are to be durable and in a color contrasting with that container. The markings are not to be altered without approval of the Society.

3. At the request of container owner, supplementary notes may be added to the marking plate to the agreement of the Society.

of the subject

![]()

Ch 2